| Thrust bearing pads | |

| Self-lubricating Bearings | |

| PTFE Plate | |

| UHMWPE Plate | |

|

|

| Thrust bearing pads(PTFE), Polytetrafluoroethylene(PTFE) Plate, UHMWPE, Self-lubricating Bearings, Solid-Lubrication Bearings |

|

|||||||||||||||||||||||||||||

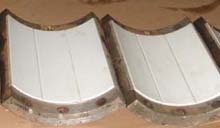

| Thrust bearing pads(PTFE)/ Elastic metal-plastic(EMP)thrust bearing pads (COB-SRIM 090) | ||||||||||||||||||||||||||||||

Thrust bearing pads(PTFE)/ Elastic metal-plastic(EMP)thrust bearing pads structure & performance: PTFE for the surface layer,chelate of copper wire and orderly spring pad to do in the middle layer of steel to the bottom of the composi-tion. PTFE through a special process with the copper wire spring mattress solid combination of metallic plastic known as the composite layer. After a special process it brazing into steel. |

||||||||||||||||||||||||||||||

| Semi-finished products | Thrust bearing pads(PTFE) | Packing | ||||||||||||||||||||||||||||

.jpg) |

|

|||||||||||||||||||||||||||||

| Visit | inspect | Test | ||||||||||||||||||||||||||||

| THRUST BEARING PADS(PTFE) certificate 1.National certificate of THRUST BEARING PADS(PTFE) new products(1995 year). 2.THRUST BEARING PADS(PTFE) certificate of national scientific & technological achievements(1995 year). 3.THRUST BEARING PADS(PTFE) First prize of national scientific & technological progress(1994 year). 4.THRUST BEARING PADS(PTFE) Support unit for the national scientific and technological achievements(1996 year). |

||||||||||||||||||||||||||||||

TECHNICAL SUPPORT |

||||||||||||||||||||||||||||||

| Thrust bearing pads(PTFE) of the outstanding characteristics. Thrust bearing pads(PTFE) design parameters. Description of installed for thrust bearing pads(PTFE) Installation manual of thrust bearing pads(PTFE) Thrust bearing pads(PTFE) production process Thrust bearing pads(PTFE) production check process Oil film pressure and area Calculation of the report for Thrust bearing pads(PTFE) Applications area of thrust bearing pads(PTFE) Appliction Units of Thrust bearings pads(PTFE) |

||||||||||||||||||||||||||||||